-40%

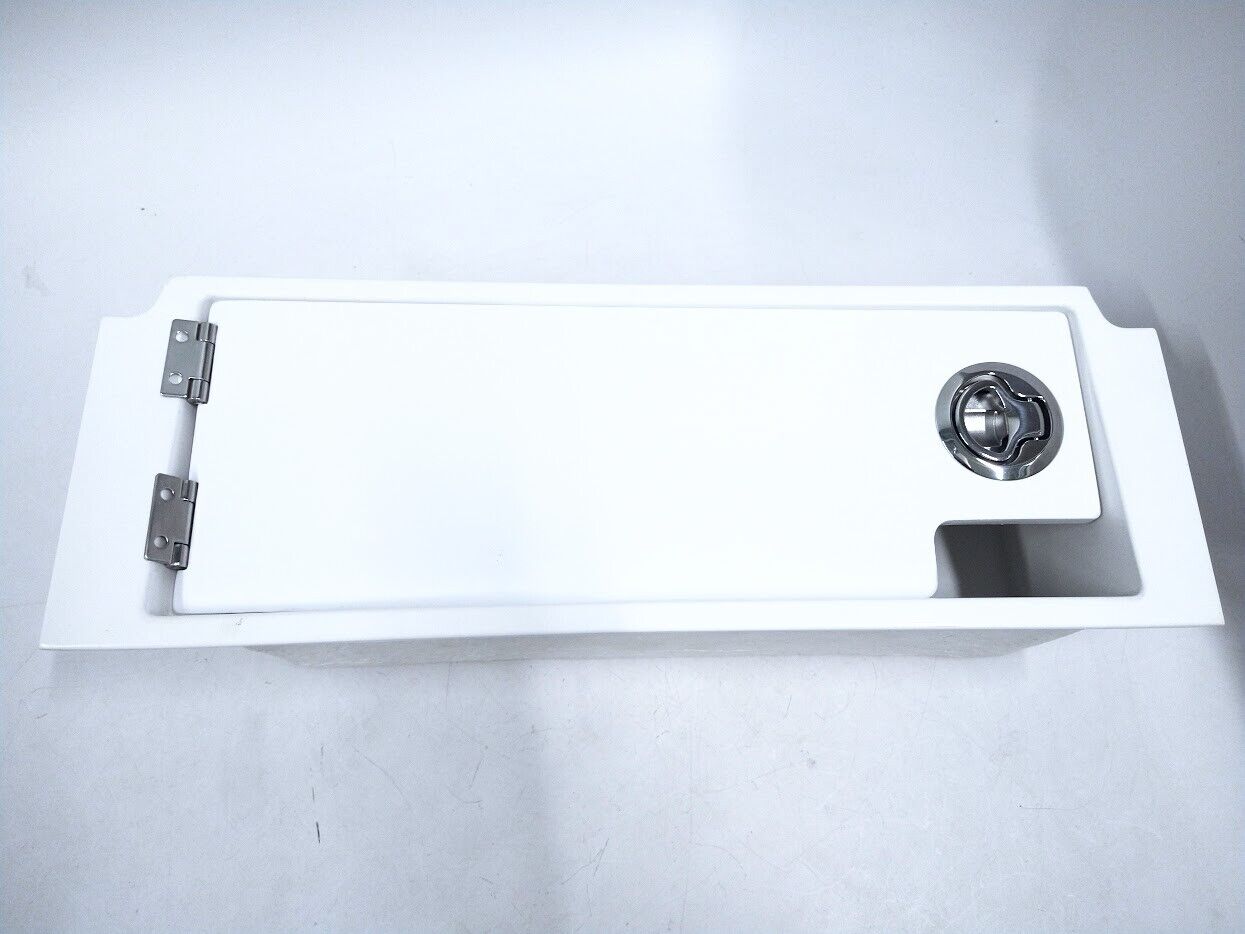

Boss Outboard Boat Motor Stand Bracket Cart Dolly Storage Heavy Duty

$ 30.61

- Description

- Size Guide

Description

From big to small outboard boat motors, the Boss DIY outboard boat motor stand holds them all! Skeptical? Check out the reviews from other customers on this motor bracket mount. They are satisfied! This is no ordinary outboard carrier cart. The ultra heavy duty design ensures this outboard motor dolly will be the only one you ever need. From Yamaha, Evinrude, and Mercury to Honda and Suzuki, the Boss Motor Stand is the go-to for all outboard boat motor storage and dolly applications.Be a Man. Make a Stand!

How to Make a DIY Ultra Heavy Duty Outboard Boat Motor Stand - YouTube

Video will open in a new window

Using the eBay App? Paste link into a browser window:

[isdntekvideo]

Thank you for looking and for your business. We appreciate your support!

Have problems or questions? Simply reach out and we will get back to you ASAP!

Important:

You supply the wood

to make a multi motor stand two sets of brackets are required

Here are instructions to cut the wood please copy and paste and print.

Here is instructions for the Uni- Motor Stand You’ll Need 1) One 2X8X10 2) 12 sheet Rock screws or screws of your choice 2” long .187 Dia From the 2X8X10 cut Three 2 foot pieces for the base From remaining piece of 2X8X10 cut a 3 ft piece, ( this part is optional, on one end of the 2X8X36” piece you just cut, cut a 7 degree angle on one end, so it sits flat on the base when assembled.) That’s it for the cutting. You can now assemble the brackets if you haven’t done so already, remove a plastic cap from each end of the ½” shafts, slide ½” rods through all holes in one bracket then slide other bracket over all rods and reattach plastic cap.

Now with the 2X8X2ft piece you cut, slide bracket on @ 2” of base now slide in 2X8X36 piece you cut with the 7 degree angle sitting flush on base. Position base over last 2X8X2 ft. pcs. All sitting parrallel and attach all with screws. In the brackets are four 3/16 holes to accept screws to hold brackets secure to stand although this is optional I do recommend fastening secure.

Here is instructions for the Multi Motor Stand

You’ll Need 3) Two 2X8X6 4) Two 2X4X8 5) 0ne 2X6X8 6) Eight ½ inch bolts 3 ½ inches long 16 Washers and 8 nuts 7) 24 sheet Rock screws or screws of your choice 2” long .187 Dia. From each of the 2X8X6 cut a 2 foot piece (from each) for the base From remaining pieces of 2X8X6 cut a 3 ft piece, ( this part is optional, on one end of the 2X8X36” pieces you just cut, cut a 7 degree angle on one end of each piece, so it sits flat on the base when assembled.) That’s it for the cutting. You can now assemble the brackets if you haven’t done so already, remove a plastic cap from each end of the ½” shafts, slide ½” rods through all holes in one bracket then slide other bracket over all rods and reattach plastic cap. Now with the 2X8X2ft pieces you cut, attach at 90 degrees and flush with corners to each end of 2X4X8, the other 2X4X8 attaches parallel to 1st 2X4X8 leaving 2 inches of over hang from (front of 2X8X2ft. (Base) ). Multi Motor stand base being assembled slide bracket on 2” over hang on both sides of base now slide in 2X8X36 piece you cut with the 7 degree angle sitting flush on base. In the brackets are four 3/16 holes to accept screws to hold brackets secure to stand although this is optional I do recommend fastening secure. Attach the 2X6X8 to the uprights four inches down from top of uprights with ½ inch bolts in the configuration of your choice